-

Gesamte Inhalte

415 -

Benutzer seit

-

Letzter Besuch

Inhaltstyp

Profile

Forum

Kalender

Shop

Articles

Alle Inhalte von keuk

-

Innenrotorzündung für Vespa

keuk antwortete auf dr. vespa's Thema in Vespa V50, Primavera, ET3, PK, ETS etc.

Thank you, I will try this. Envoyé de mon iPhone en utilisant Tapatalk -

Innenrotorzündung für Vespa

keuk antwortete auf dr. vespa's Thema in Vespa V50, Primavera, ET3, PK, ETS etc.

Hi, I have a 13° grad PVL for a racing scooter, what is the classic setup to use ? How much degres at 3500/4000 for example ? I have a Wforce58x54 with 127/193 timings. Thank your very much. Antoine -

AF Parts Achsaufnahme iVm BGM PRO SC/F16

keuk antwortete auf Lenki's Thema in Vespa V50, Primavera, ET3, PK, ETS etc.

Hi Lenki, What upper plate did you mount ? Do you have an offset of the center hole ? About the 1mm clearance, the largeness in the aria where you mount the shock should be the same than on the original piaggio. You can use a spacer to correct this. You can make your own or buy one from sip or sck, I think I saw this part, I have to check. -

Nur mal schnell ‘ne Smallframe-Technikfrage

keuk antwortete auf Kotzerider's Thema in Vespa V50, Primavera, ET3, PK, ETS etc.

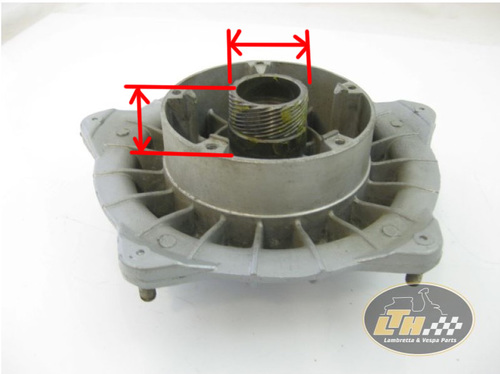

Hello, Could someone give me the dimensions of the speedo gear in a LML hub ? Internal / external diameter & lenght. Thank you very much. -

Zündung Polini Evo digital

keuk antwortete auf salih's Thema in Vespa V50, Primavera, ET3, PK, ETS etc.

Here are the curves from the Polini website: http://www.polini.com/dep/PI454.pdf Curves fall between 8 / 9000 depending on the curves compared to the PVL with digitronic which curves fall at 7000. -

Innenrotorzündung für Vespa

keuk antwortete auf dr. vespa's Thema in Vespa V50, Primavera, ET3, PK, ETS etc.

Hi, What is in theory the best thing to do when setting up the variable ignition ? dealing with the kick at 6/7000 or looking at the power pic arround 9/10000 ? I made an excel with the different ignition possibilities to try to understand. PVL 13° Ref 1443 PVL 22° Ref 1077 PVL 3° Ref 1442 + Malossi Digitronic Vespatronic I played with the offsets corresponding to the stator position on the casing, to bring the curves closer to be able to compare them. -

Thank you for this nice week end ! Lulu, Romain "Baguette" and I, had a lot of fun with you guys. Keep rocking !

-

Zylinder -PARMAKIT 144ccm W-Force

keuk antwortete auf olipv's Thema in Vespa V50, Primavera, ET3, PK, ETS etc.

Thinking to the way to shorten the inlet of my W-force I found a YZ 250 inlet on google with the fixing holes very similar to the original one. + It has a small curve to get closer to the side panel. Has anyone tried it or something similar ? -

I have exactly the same problem, when I'm at low rpm and throttle at full gaz, the scooter has "Stottern" and it seems that I have also this behavious in curves. My setup: Polini 177, Si24 55/160 160/BE3/132, si24 original smmimerdeckel/ 2,2mm hole in the vergaser , Sip road Maybe the 2,2mm hole is too much, the DRT has 1,8 accoding to sip.. ?

-

Hello, I wonder what Magura model is this ? Any feedback ? http://www.scooter-center.com/product/7676540/Brake+master+cylinder+MAGURA+Radial+piston+11mm+rhs?meta=7676540*scd_ALL_en*s934393145952*magura*1*1*1*16

-

Ok, and what diameter should I do ?

-

Thank you for the answer ! Are thoses holes the 1,8mm holes they are talking about on sip ?

-

Hello, I would like to use a cosa Schwimmerkammerdeckel on my PX177 because I have problems on voll gaz on the highway. My actual setup is Polini 177 ajusted / Si24-24E 160/BE3/138 and 50/160 with a sip road. How come the cosa model sell by DRT and Pinasco are so expansive, are they necessary or can I use a standard cosa model ? Thank you. DRT: http://www.sip-scootershop.com/de/products/couvercle+de+la+chambre+du_128295t7 COSA http://www.sip-scootershop.com/de/products/schwimmerkammerdeckel+dello_12832540

-

SF kupplung Hartz4 bzw. Hartz5...........

keuk antwortete auf gravedigger's Thema in Vespa V50, Primavera, ET3, PK, ETS etc.

Hello, What is the minimum clearance I need to have a correct running ? Right know I have between 1,8 and 2,2mm between the last disc and the bell. I have a 0,5mm spacer behind the christmas tree and I have one more that I can add if necessary. Greetings. -

neues DRT Getriebewunderland

keuk antwortete auf Brosi's Thema in Vespa V50, Primavera, ET3, PK, ETS etc.

I would like to use the Runner tree on the left on my engine but there is a misalignment in the 4th gear. Is there a way to correct this ? -

SF kupplung Hartz4 bzw. Hartz5...........

keuk antwortete auf gravedigger's Thema in Vespa V50, Primavera, ET3, PK, ETS etc.

Hello even with another primary it doesn't work, the springs don't stay in place when I remove the 2 screws.. Anyone has a tip ? With a bit of dremel in the casing would it fit all together ? -

SF kupplung Hartz4 bzw. Hartz5...........

keuk antwortete auf gravedigger's Thema in Vespa V50, Primavera, ET3, PK, ETS etc.

Dammit ! The answer is in front of me, I have machined the primary for the DRT repair kit, so the housing in the primary is bigger than is the Hartz plate and bell... so it is a pain in the ass to mount it, I'll try to find another primary gear to check. -

SF kupplung Hartz4 bzw. Hartz5...........

keuk antwortete auf gravedigger's Thema in Vespa V50, Primavera, ET3, PK, ETS etc.

Hello, I need to mount the primary and the repair kit alone in the engine casing ( the bell doesn't pass), but it's very touchy to make the springs fit, so I can't imagine in the casing. It's very hard to keep the spring in place when I remove the two screws. Do you have a trick ? I use DRT spings. -

Neuigkeiten, Gerüchte, Produktankündigungen

keuk antwortete auf Brosi's Thema in Vespa V50, Primavera, ET3, PK, ETS etc.

Wow ! Geil! Any pictures of the exhaust ? -

Well...nice job ! The transfert in the casings are not even matched with the cylinder ? And you kept the flange inside the transfert ports ?

-

Then WOOAWWW Great !!

-

51 stroke ! ?

-

What does that mean ?

-

neues DRT Getriebewunderland

keuk antwortete auf Brosi's Thema in Vespa V50, Primavera, ET3, PK, ETS etc.

Hello, for a race use, I would like to use a longer 1st and 2nd, is it smart or not to combine it with a DRT runner christmas three with its shorter 3th and 4th ? I'm afraid that the gap between 2 and 3 would be too short ?