-

Gesamte Inhalte

37 -

Benutzer seit

-

Letzter Besuch

Letzte Besucher des Profils

Der "Letzte Profil-Besucher"-Block ist deaktiviert und wird anderen Benutzern nicht angezeit.

Leistungen von GiulioEX125E

member (3/12)

14

Reputation in der Community

-

Es ist wirklich schön, herzlichen Glückwunsch Ich habe Lust, ein ähnliches Projekt auf meiner Vespa zu starten

-

Ist es möglich, ein komplettes Fotoset dieser Vespa zu haben? sie ist wirklich schön. Ich spreche nicht gut Deutsch, sorry, aber die Vespenliebe kennt keine Sprache

-

[Entschuldigung für mein Deutsch, ich benutze Google Translate] Ich versuche, ein HP-Schwungrad an einen PX-Motor anzubauen. Die Statorplatte habe ich bereits gedreht, damit ich den richtigen Zündzeitpunkt habe, ich habe es mit der Stroboskoppistole überprüft und es ist ok. Aber: Es dreht nicht über 6.000 U / min. Es stottert wie wenn der Tonabnehmer stirbt. Ich habe gelesen, dass dies durch eine schlechte Ausrichtung des Pickups mit dem Schwungrad verursacht wird, also habe ich versucht, verschiedene Unterlegscheiben als Abstandshalter hinter der Statorplatte zu verwenden. Ich habe 1/1.5/2/2.5/3 mm ausprobiert, aber nichts hat das Problem behoben. Die Person, die mir das HP-Schwungrad verkauft hat, sagte, "es funktionierte gut an meinem Motor" (keine PX-Engine). Keine Ahnung ob das stimmt oder nicht Der Stator und der Tonabnehmer funktionieren einwandfrei, da sie mit den PX-Schwungrädern keine Probleme haben und bis zu 10-11.000 U / min drehen. Ich habe sie auch mit dem Tester überprüft, und die Werte sind alle gut. Haben Sie eine Ahnung, warum das passiert?

-

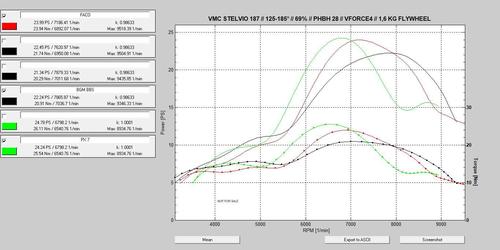

VMC Stelvio 187 schlechte Leistungen nur mit BGM BBS

GiulioEX125E antwortete auf GiulioEX125E's Thema in Vespa PX, T5, Cosa etc.

Die Frage war: Warum schneidet das BBS bei dieser Motorkonfiguration so schlecht ab? Für mich ist es ein gutes Setup für eine BBS, es hat keine niedrigen Timings wie 110-160° oder ähnliches, aber es hat auch nichts zu hohes wie 135-198° und so weiter... Das könnte stimmen, ehrlich gesagt habe ich das auch schon gehört. Naja kommt drauf an. Ich habe auch eine Modifikation an der Faco-Box vorgenommen und es lief wirklich gut, sogar über meinen Erwartungen. Die Modifikation, die ich am BBS vorgenommen habe, ist keine Idee von mir, aber White One Racing (italienische Tuner, ziemlich aktiv auf Youtube, vielleicht haben Sie schon davon gehört); Sie testeten die Modifikation mit großartigem Ergebnis, zuerst an einem getunten 200er-Motor (210 oder 221, ich erinnere mich nicht), dann an einem getunten 187er-Motor. Deshalb habe ich ihre Anleitung zum Ändern des BBS befolgt. Aber in meinem Fall hat es nichts gebracht, oder vielleicht +1 hp wie gesagt. Selbst ohne Berücksichtigung der Modifikation, die ich an der BBS vorgenommen habe, funktioniert sie meiner Meinung nach immer noch ziemlich schlecht. Und ich verstehe nicht warum. -

If someone wants to give me some help with the BGM BBS in this topic... I don't know why it is performing so poorly while all the other exhausts I tried are doing quite good...

-

Ich spiele mit einem VMC Stelvio 187 herum. Dies ist das komplette Setup: - Zylindersteuerzeiten 125-185°, Auslassbreite 69% - Squish: 1,0, Kompressionsverhältnis: 12,75 - DRT Drehschieber Kurbelwelle 60x110 - LML-Membrangehäuse stark verschweißt und im Ansaugbereich gefräst (riesiger Durchgang) - PHBH 28 mit vforce4-Stimmzungen - Pinasco 1,6 kg Schwungrad, Ducati statische Zündung um 20° - 22/68 Primär, 16/19 Cluster, 4. Gang z35 Ich habe diesen Motor mit verschiedenen Auspuff ausprobiert, und er funktioniert mit allem gut, ABER NICHT mit dem BGM BBS! Ich werde hier einige Diagramme mit allen getesteten Auspuffsystemen hinterlassen (Faco-Box ist fast identisch mit der Polini-Box; PX 7 ist Resonanzauspuff, die von einem Freund hergestellt wurden), und Sie können sehen, dass die Leistung von BGM BBS insgesamt ziemlich schlecht ist, insbesondere für die Drehmoment. Außerdem ist das von mir verwendete BBS kein Standard, es wurde modifiziert. Ich fügte eine "Reflexionswand" 4 cm vom letzten Kegel entfernt hinzu, dann entfernte ich die seltsame Wand in der Box und ersetzte sie durch eine Standardwand mit einem einzigen Loch. Zuletzt entfernte ich das 16-mm-Rohr und schweißte ein 18-mm-Rohr. Aber das wurde auf einem vorherigen "Schritt" mit diesem VMC (Standard Low Timings) gemacht und es hat nicht viel gebracht, weniger als +1 hp Was denkst du? [Entschuldigung für mein schlechtes Deutsch ]

-

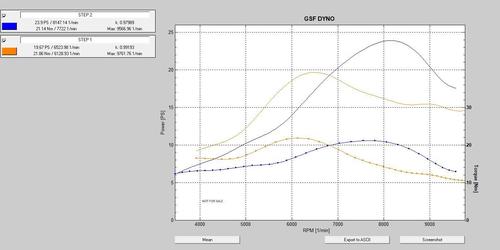

Here are some tests I did on my VMC Stelvio with reed valve and the BGM BBS. I did a simple comparison between 2 different engine configurations. Step 1: VMC Stelvio 115-170°, exhaust 64%, squish 1.0, CR 11.5 Full circle crank 57x110 LML cases, heavily welded and milled on the intake area to open a big passage PHBH 28 on vforce4 reeds Static Ducati ignition at around 18° 2.1 kg flywheel Step 2: Timings raised to 125-185°, exhaust widened at 69%, squish 1.0, CR 12,75 Cut rotary intake crank, 60x110 The rest was the same as step 1. Here you can see the comparison between the 2: The BGM BBS I used is modified by me, by adding an internal wall at around 4 cm from the last cone; I also removed the small "box" inside the box (:D) and replaced it with a standard wall with one single hole, then the final tube of 18mm internal diameter. This modification showed basically no result on the step 1; on step 2 I only tried the modded version of BBS so I have no idea, sadly. Overall, I am not super satisfied with the BBS... In the step 2, it lost peak torque, it only gained some peak power thanks to the higher revs.. I still have to make some adjustements, for example the final part of the exhaust duct on the cylinder is really small even for the original exhaust port, now that I raised it and widened it, it must be also widened in all the lenght, from the cylinder to the exhaust (hard to explain sorry, I hope you get it). What do you think? Any suggestion? This BBS isn't making me really happy

-

T5 vs PX engine (NOT basic tuning)

GiulioEX125E antwortete auf GiulioEX125E's Thema in Vespa PX, T5, Cosa etc.

Nice, I will surely give it a read! Thanks As far as I know (never had them in my hands), Pinasco T5 cases have more material on the cluster area, which is already a huge upgrade from Piaggio cases. I would prefer reed intake, because I already have everything it needs. Also I have very limited experience in rotary intake, and finding the best timings would be quite a pain... Overall I think this T5 project would cost too much for a small (if any) performance increase from my current PX engine. Piaggio T5 cases cost quite a lot, Pinasco T5 cases even more. There is no garantee that a 172 Malossi would perform better than my current 187 MHR on PX, and the only relevant difference would be the bigger transfer ports. Uhmmmm the more I think of this T5 project, the less smart it sounds -

T5 vs PX engine (NOT basic tuning)

GiulioEX125E antwortete auf GiulioEX125E's Thema in Vespa PX, T5, Cosa etc.

The 251 Pinasco surely is an interesting cylinder, I especially like its huge transfer ports (way bigger than a Quattrini 244 for PX, for example) but I have 2 major doubts on it: 1) 251cc (and all big bore in general) produces a lot of torque, I don't think the original Piaggio T5 cases would last long. It would probably be needed to use Pinasco T5 cases, that are reinforced on the cluster area, where PX and T5 cases usually crack 2) the price of the Pinasco 251 is higher than the Malossi 172, and as stated in n.1, it would also require the reinforced Pinasco T5 cases (in my opinion) so the price would be even higher So you think the 172 Malossi for T5 isn't a good cylinder? If raised to around 130-190°, do you think it has less potential than a 172 M1X / 177 VMC Stelvio / 177 Malossi MHR, for PX? -

Hi everyone! As usual, sorry in advance but I don't speak german so I'm writing in english since most of you can understand it (I hope). So I am here to ask a simple question: considering the same "tuning level", can a T5 engine have the same performance of a PX engine? I can use the example of a PX engine that I built recently: 187 Malossi MHR, 127-190° 28 or 34mm carb, vforce4 reeds on bolted-on MRP block LML cases heavily welded and milled in the intake area to have a big area for the mixture to come in 60x110 Tameni crank Pipedesign Bullet + Megadella XL (used both - not at the same time ) GSF dyno showed something around 27-28hp (the exact value is irrelevant, we all know it can also show 35hp if I change some values...). But even ignoring the hp value, generally speaking I assume we all know how an engine like this can perform, more or like. So I'm curious of what can be achieved with the same level of tuning, but starting with a T5 base. Example: Malossi 172 cylinder (I think it's the only "good" one for T5), timings around 130-190° or something like that bolted-on reed block, no welding 28 or 34mm carb long stroke crank (still no idea which one, its all hypotetical) expansion chamber exhaust or box exhaust (Megadella XL, BGM BBS, something like that - not interested in Polini box, Sip Road etc) Do you think something like that (I know the engine description for the T5 is very generic), can perform as good as the PX engine, with the same level of tuning? More specifically... I'm interested in a T5 project because the T5 engine is the natural evolution of the PX engine, so it has a "stronger" crank, a better bearing for the flywheel side, and last but not the least, it has bigger transfer ports. Regarding transfer ports specifically, I also would like to do something like this, if it is possible: welding the area as in the picture, both on the cases and on the cylinder, to have a bigger surface so that I can mill even bigger transfer ports; this way the would start looking similar to a modern 2stroke engine, where the transfer ports usually are really huge. Original T5 ports are already big, but since this welding and milling work isn't so expensive or complicated to do (I hope!), I would really like to try. So short version: 1) do you think PX and T5 engines with the same tuning level, can achieve the same performances? 2) what do you think about the welding & milling idea for the maxi transfer ports? Thanks in advance :)

-

[High transfer - high exhaust] VS [high transfer - low exhaust]

GiulioEX125E antwortete auf GiulioEX125E's Thema in Vespa PX, T5, Cosa etc.

@AIC PX I couldn't find anything related to my question, in those 2 topics :( You surely tested a lot in terms of cylinder timings, but I didn't find a test where you only lowered the exhaust, keeping the transfers at the same level. You tested blowdown changes but in all the tests, you also changed transfers... -

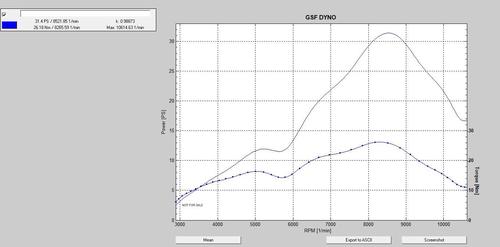

Hi everyone, first of all excuse me for writing in english, but I don't speak german I have a question about cylinder timings, I would like to discuss it in a "unspecific" way, without mentioning any specific cylinder brand, carb type, exhaust, etc. Let's say I have an engine that has 130-190°. This is the power/torque graph: 31.5 hp @ 8500 rpm 26.1 nm @ 8200 rpm From general knowledge, if I simply lowered both the transfer and the exhaust (let's say 125-185°), the torque band would move to the left, giving me more torque at lower rpm but also less peak power and less over-rev. Now: how would this curve change, if instead I only lowered the exhaust? Let's say, from 130-190°, to 130-180°? How does lowering the exhaust only, affect the curve? If I lower the exhaust only, it probably won't be exactly like I just described for lowering both transfer and exhaust, right? If someone here already experimented this combination (high transfer-low exhaust), feel free to draw on my graph to show how you think the curve would change.

-

Malossi MHR 177 - Die neue Legende

GiulioEX125E antwortete auf MaRi's Thema in Vespa PX, T5, Cosa etc.

Did anyone here maybe measure the tolerances between piston and bore on the MHR? -

Malossi MHR 177 - Die neue Legende

GiulioEX125E antwortete auf MaRi's Thema in Vespa PX, T5, Cosa etc.

I know google translator, but I also know how bad it is. Since most of the people can read english, I think it is better to simply write in english. Also since there is a lot of technical words when talking about tuning, google translator can really fuck it up badly and the whole sentence might become hard to understand. So what kind of improvements did this bring? Higher squish, more retarded ignition and learner carb setup... I feel like this made more power at the overrev? Anyway, I am about to re-install my dear MHR. This time tho, I would like to test the VMC piston on it. Ring-pins fall in the 3rd port for both the cylinders, so no issue. I will use the VMC head to make sure it copies the vmc piston perfectly. VMC piston is about 1mm higher, so I will need to raise the cylinder 1mm to get the right squish and cylinder timings. The last thing that I'm trying to figure out, is the tolerances. I live in a small city and its a PAIN to find someone with the tool to measure. I went to a workshop and they measured the following: cylinder: 62.97 piston: 62.78 That gaves me a tolerance of 19 cent. What the hell? I suspect those values are not precise. Also 62.97 bore... that should not be possible, it should be 63.00 or maybe even something more like 63.03, if the coating is reduced a little bit. Also they guy said that the piston is not a cone anymore, because he got the same measure on 3 different heights of the piston. So... all this makes no sense to me. I tried to find another workshop with the right tools, again it was a real pain, now I found it, I left them the cylinder and piston, but they are full of other jobs to do, it's been 1 week already and no news from them. The situation in my city is so sad... None does this "precision stuff" anymore, it's an art that's already dead, so sad. Anyway: I will wait for news and then I will see if it is possible to use a VMC piston on the MHR. I'm not sure it will bring benefits of course, but I think it's worth trying. -

Malossi MHR 177 - Die neue Legende

GiulioEX125E antwortete auf MaRi's Thema in Vespa PX, T5, Cosa etc.

Well... VRONE cases surely are nice, with a good intake even if not optimal (ooptimal = bfa intake style, carb pointing backward and reeds pointing forward). Vespower ignition, I dont know, 1.2kg flywheel sounds a little bit too light, considering the lightest largeframe clutches weight around 1kg (Crimaz) or 1.3kg (Sip or standard Piaggio) so its 1-1.3kg on the clutch vs 1.2kg on the flywheel... I dont like that. Anyway, my MHR with stock timings, on LML cases with the intake opened up and a fullcircle crank, with a phbh28 on vforce4 reeds and various box and resonance exhausts, pulled around 21-23 hp and 20-23 nm. Did you get better results with your setup? Did you dyno it already?